In industrial environments where hazardous gases are a concern, having a reliable gas detection system is essential for safety and operational efficiency. One such advanced gas detection system is the XNX Honeywell Analytics. This state-of-the-art device provides real-time monitoring and ensures a safe working environment in industries such as oil and gas, chemical processing, and manufacturing.

In this comprehensive guide, we will explore the features, benefits, installation process, and applications of the XNX Honeywell Analytics system. Whether you are looking for an industrial gas detection solution or simply want to understand the latest safety technologies, this article will provide valuable insights.

What is XNX Honeywell Analytics?

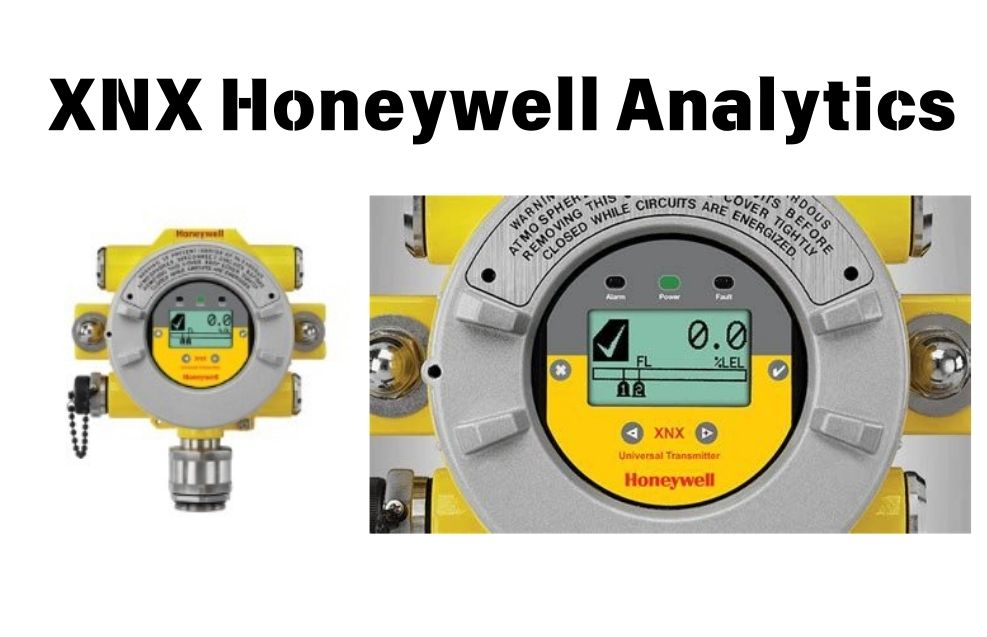

XNX Honeywell Analytics is a universal gas transmitter designed to work with multiple gas detection technologies. It is developed by Honeywell, a leading name in industrial safety and automation. The XNX transmitter is highly adaptable and can support electrochemical, infrared, and catalytic bead sensors to detect toxic and combustible gases.

Key Features of XNX Honeywell Analytics

- Multi-Gas Compatibility – Works with a variety of sensors to detect toxic, oxygen, and combustible gases.

- Universal Transmitter – Supports multiple communication protocols such as HART, Modbus, and Foundation Fieldbus.

- Rugged Design – Built to withstand extreme industrial conditions, including harsh temperatures and corrosive environments.

- Easy Integration – Can be connected with existing Honeywell gas detection systems and third-party controllers.

- Real-Time Monitoring – Provides continuous gas monitoring to ensure a safe working environment.

- User-Friendly Interface – Features an intuitive LCD display with easy-to-navigate menus.

How Does XNX Honeywell Analytics Work?

The XNX Honeywell Analytics system operates by continuously detecting gas levels in industrial environments. It uses different sensor technologies, including:

- Electrochemical Sensors – Detect toxic gases such as hydrogen sulfide (H₂S) and carbon monoxide (CO).

- Infrared Sensors – Identify combustible gases such as methane (CH₄) and carbon dioxide (CO₂).

- Catalytic Bead Sensors – Used for detecting flammable gases and vapors.

The transmitter then converts the gas concentration levels into digital or analog signals, which are transmitted to a centralized control system. This allows operators to monitor gas levels in real time and take immediate action if dangerous conditions arise.

Benefits of Using XNX Honeywell Analytics

1. Enhanced Workplace Safety

The primary advantage of using XNX Honeywell Analytics is improved safety. The device provides early warnings for hazardous gas leaks, helping to prevent accidents, injuries, and fatalities.

2. Cost-Effective Solution

By supporting multiple sensor technologies, the XNX transmitter eliminates the need for separate detection devices, reducing overall costs.

3. Scalability and Flexibility

The system can be customized to meet the specific gas detection needs of various industries, making it an ideal solution for both small and large-scale operations.

4. Reliable Performance

With robust construction and advanced sensing technologies, the XNX ensures long-term reliability and minimal maintenance requirements.

5. Seamless Integration

The device can be integrated with existing gas detection networks, providing enhanced monitoring capabilities without requiring major infrastructure changes.

Read Also : What is a Guardrail and Why is It Crucial for Safety?

Installation and Setup Guide for XNX Honeywell Analytics

Step 1: Site Assessment

Before installation, conduct a thorough assessment of the site to determine gas detection requirements, including the types of gases present and the optimal sensor placement.

Step 2: Mounting the Device

The XNX transmitter should be mounted at the correct height and location based on the specific gas properties. For example:

- Lighter-than-air gases (e.g., methane) – Sensors should be placed near the ceiling.

- Heavier-than-air gases (e.g., hydrogen sulfide) – Sensors should be placed near the ground.

Step 3: Wiring and Connections

Follow the manufacturer’s wiring guidelines to connect the XNX transmitter to the power supply and central monitoring system. Ensure all cables are properly shielded to prevent interference.

Step 4: Sensor Calibration

Calibrate the sensors according to Honeywell’s recommendations. Regular calibration ensures accuracy and prevents false alarms.

Step 5: System Testing

Perform functional testing to verify that the system is operating correctly. Check for proper signal transmission and responsiveness to gas presence.

Industries That Benefit from XNX Honeywell Analytics

1. Oil and Gas Industry

In oil refineries, drilling sites, and processing plants, gas leaks can lead to catastrophic explosions. The XNX system helps detect flammable gases, ensuring compliance with safety regulations.

2. Chemical Manufacturing

Many chemical plants handle hazardous substances that can be toxic or combustible. The XNX transmitter enhances monitoring and mitigates risks.

3. Power Plants

Gas turbines and power generation facilities use XNX Honeywell Analytics to detect leaks in fuel supply lines, protecting both personnel and equipment.

4. Wastewater Treatment Facilities

Harmful gases such as hydrogen sulfide are commonly present in sewage and wastewater treatment plants. XNX ensures safe working conditions by detecting these gases early.

5. Food and Beverage Industry

Certain food production processes involve gases like carbon dioxide and ammonia. The XNX system provides efficient monitoring to maintain product quality and worker safety.

Maintenance and Troubleshooting Tips for XNX Honeywell Analytics

Routine Maintenance

- Perform periodic sensor calibration to maintain accuracy.

- Inspect wiring and connections to prevent electrical faults.

- Replace aging sensors as recommended by the manufacturer.

- Clean the device regularly to remove dust and debris.

Common Issues and Solutions

- False Alarms – Ensure proper calibration and check for external factors like humidity and temperature fluctuations.

- Sensor Malfunction – Replace defective sensors and verify proper wiring.

- Communication Errors – Check for faulty cables and ensure correct protocol settings.

Where to Buy XNX Honeywell Analytics?

The XNX Honeywell Analytics system can be purchased from authorized Honeywell distributors, industrial safety equipment suppliers, and online marketplaces specializing in gas detection technology. It is recommended to buy from official sources to ensure authenticity and warranty coverage.

Conclusion

The XNX Honeywell Analytics is a versatile and highly reliable gas detection system that enhances workplace safety in hazardous environments. With its universal transmitter, multi-gas compatibility, and real-time monitoring capabilities, it provides a cost-effective solution for various industries.

By understanding its features, installation procedures, and maintenance requirements, businesses can implement a robust gas detection strategy to protect employees, assets, and the environment.

If you are looking for a trusted and efficient industrial gas detection system, XNX Honeywell Analytics is an excellent choice. For more information, visit an authorized distributor or contact Honeywell’s customer support team.